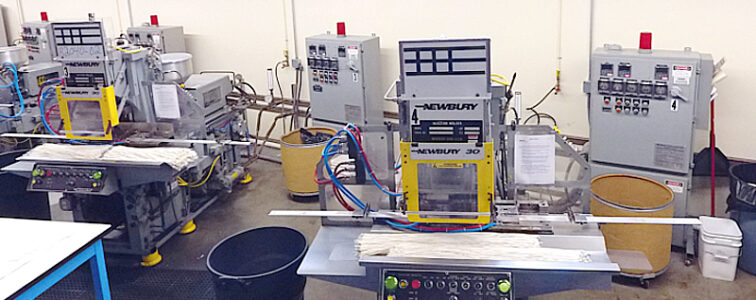

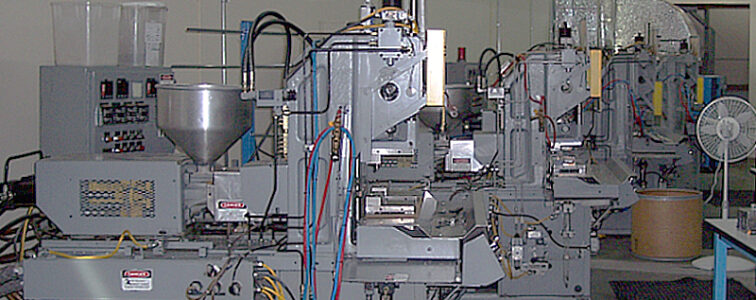

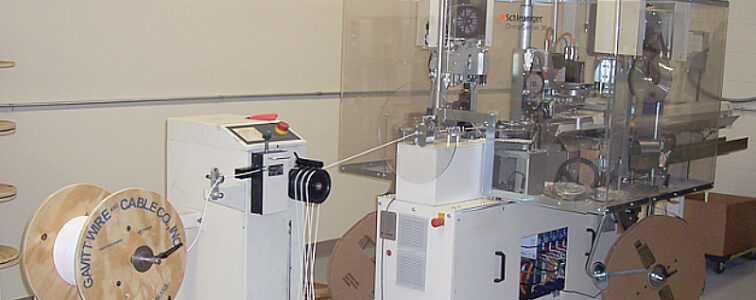

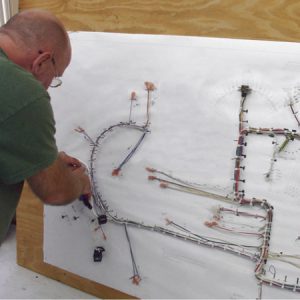

At Inside Track Cabling, we realize the importance of having high quality equipment that will exceed our customer’s requirements. Our state-of-the-art inventory of wire/cable preparation and automatic termination centers enable us to produce high quality, high volume products in a fraction of the time of our competitors.

Inside Track Cabling has an ever-expanding array of processing and terminating equipment to provide our customers with the versatility they require. Our extensive inventory of semi-automatic application equipment enables us to terminate most terminals, contacts, and connectors our industry’s top manufacturer’s produce, such as AMP/TYCO, Molex, Delphi, JST, Hirose, Deutsch, Lear, Hollingsworth, Hoffman, DMC and more.

This extensive inventory of equipment allows us to offer our customers more competitive product pricing and earlier delivery lead-times, without the added cost and delays incurred to acquire necessary tooling and equipment. It also allows us purchase and apply high volume packaged material (carrier strips, tapes, tubes, etc.), which not only can be applied more quickly and efficiently, but also enables us to pass on high-volume component pricing even when you may have lower volume requirements.

Put our experienced staff to work for you and send us your request for quote. If you would prefer to come to our facility and deliver your samples or drawings in person, we would be happy to give you a tour of our facility so you can see our capabilities first hand. And, we always welcome you to contact us for any other information.